Production technology of MAFs

The production technology of MAFs at the TAF-87 production facility varies depending on various factors, such as materials, purpose, dimensions, and other requirements. However, the main manufacturing steps include the following steps:

- Design and planning: This stage includes the development of the design of the MAF, the determination of dimensions, the selection of materials and technical characteristics, as well as the development of construction drawings by TAF specialists.

- Preparation of the work area: This includes cleaning and preparing the site for construction, installing a foundation or underlayment, if necessary.

- Fabrication of the frame: The frame of the MAFA is built according to the plans and drawings, using selected materials, such as metal, wood.

- Insulation and finishing of walls and roof: If required, the walls and roof of the MAF can be insulated with insulating materials such as 50 mm or 100 mm mineral wool, and also treated to ensure waterproofness and durability.

- Installation of windows and doors: Installation of windows and doors, which can be made of metal, wood or plastic, depending on design and functionality requirements.

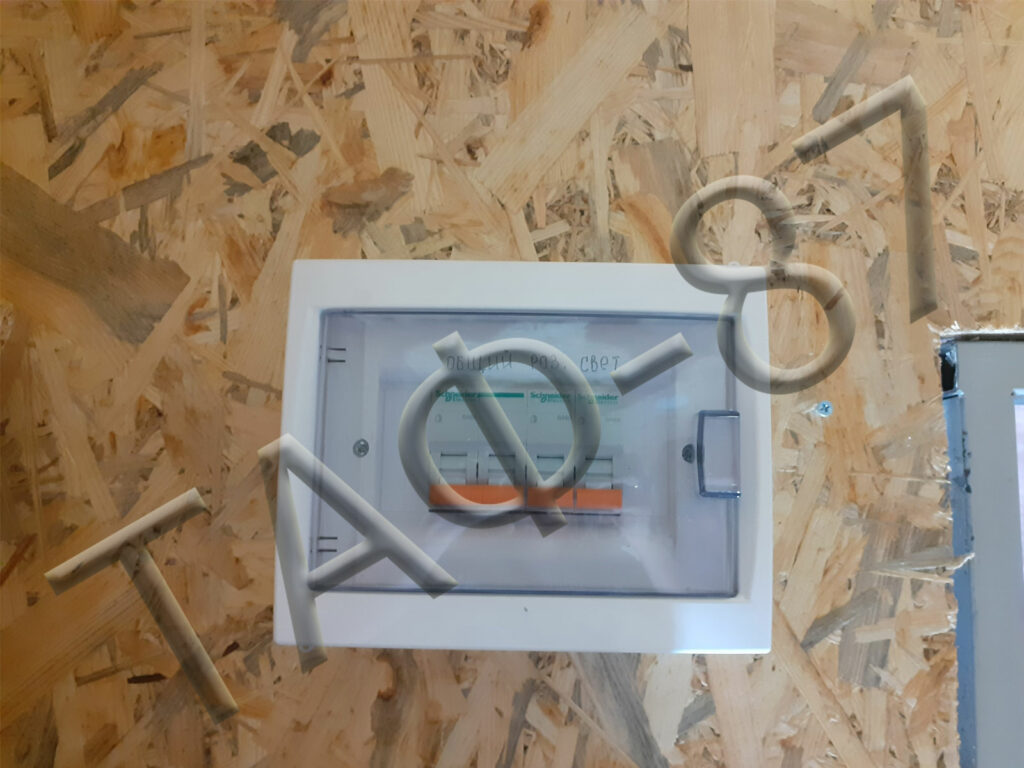

- Finishing and Finishing: This includes the installation of the roof, wall cladding, installation of electrical systems (if required) and the completion of internal and external finishes.

- Testing and quality assessment: After the construction of the IAF is completed, the product is tested to verify quality and compliance with safety standards and building codes.

This is only a general description of the production process of MAFs.